VFFS Pillow bag with zipper

August 9, 2022

Zipper is a word created from the sound of closing “Fastener” which had developed for solving the inconvenience to tie the shoelaces and the purpose of the fastener is repeating open-close.

When we can’t eat up or use up the food, we think ‘we should preserve it’. But what would you do if you don’t have clips or rubber band to close the package? Even if you have these items to close the package, haven't you experienced the snacks get soft by moisture when you eat them again because the bag was not sealed completely? The zipper-bag can solve the problem, it can be sealed and keep the food fresh.

The product in zipper bag is very convenient and popular for consumers. Many people would choose the zipper bag if the same products on the shelf and one is the package with zipper and the other is not. The package with zipper stands out and can catch people’s attention more than the normal package; the sales would go well too.

Having zipper with the bag, we can seal the bag and keep the products longer when we can’t use up the contents. We don’t need to replace to other container but keep in the same bag. This means the product information will remain catching our attention and we memorize the package design. If the foodstuff can’t be used up at once, the consumer would think to buy it if the package has zipper.

The products such as the cereals, the powder beverages or the seasoning powders are probably not supposed to be used up the pack at once. Those products are recommended to add zipper on the package. As mentioned above, there would be more chances the consumer choose the products, and more than an anything, the product will be provided in fresh and eaten delicious that the manufacturer produce with confidence. Who ate your products may become a fan as repeat customer and that is such an assuring for keeping good sales.

VFFS Pillow bag with zipper

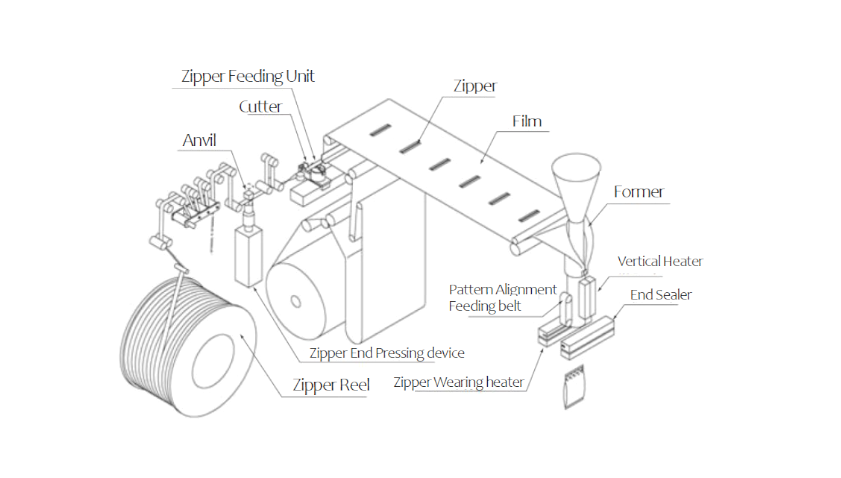

The typical packaging machine for food products is form-fill sealing machine (or called flow pack machine). The form-fill sealing machine is the packaging machine to feed film material from a roll, form the film into tube shape, then seal the back and bottom of the tube, and fill the goods material, seal the top, then finally cut the film and complete as a bag.

Tam VFFS machine with zipper is a model able to attach the zipper in the process of feeding the film from the reel. The operation can be chosen for producing bags with or without a zipper, and can add various options such as adding punch hole or producing block-bottom gusset bag.

Vertical Form Fill Seal Machine(VFFS) with In-line Zipper Model TWN-Z

The features and advantages of the VFFS with zipper

The development of the VFFS machine zipper model has started in 2004. The first case was a new project for changing packaging style of powdered beverage. The followings are the features and advantages of the VFFS machine for zipper bag.

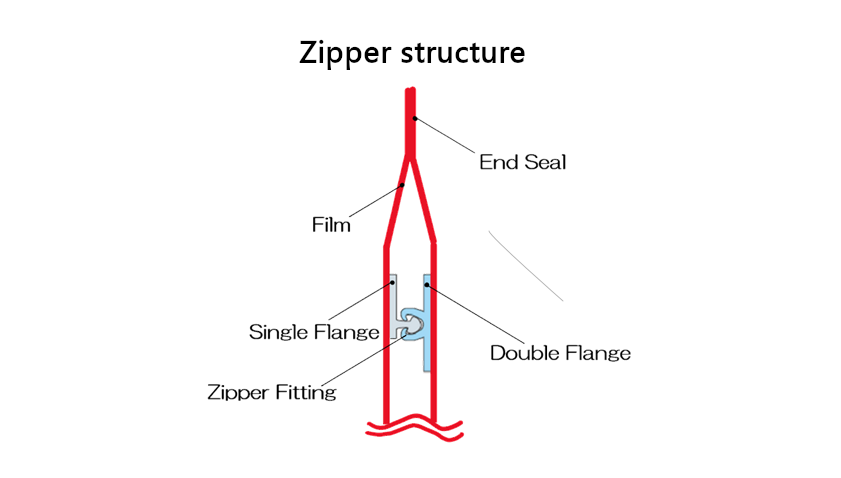

The purpose of the development is the sealability and air tightness since the filling contents is powdered beverage and these are the features of the zipper.

-

■ Inspection 1. Sealability: Check the leakage from the zipper part by filling the penetrant and observing 8 hours.

■ Inspection 2. Air tightness: Check if any change occurs such as moisture absorption by filling the powdered beverage, and left it for 1 week.

Zipper bag is produced by attaching a zipper at the top opening of the bag to re-open. Since the zipper is attached in a process of feeding film roll, the film cost is less expensive than the pre-made bag with zipper.

How to apply zipper

The zipper is fed from the zipper reel. The both end of the zipper length are pressed by ultrasonic device. The formed zipper is cut in prescribed length, and then the zipper is adhered on the film that is fed from the film roll. The film is then formed in tube shape, sealed the rear side and bottom side. The product is filled into the tube, and then the bag is sealed and cut on top. The zipper flange is sealed at the same time of the bottom seal and the fitting part is pressed again. This process will keep the bag sealability and air tightness.

The advantages of the VFFS package with zipper

■ Successful installed experiences

As we described, the first zipper machine was delivered and installed in 2004. After that, we experienced various products such as cocoa, cereals, candies, chips and sausages, and etc. Any of those projects was changing the packaging style from the existing products. Adopting the re-open and re-close bag style increased the level of convenience and reduced the film material cost.

■ Re-closing

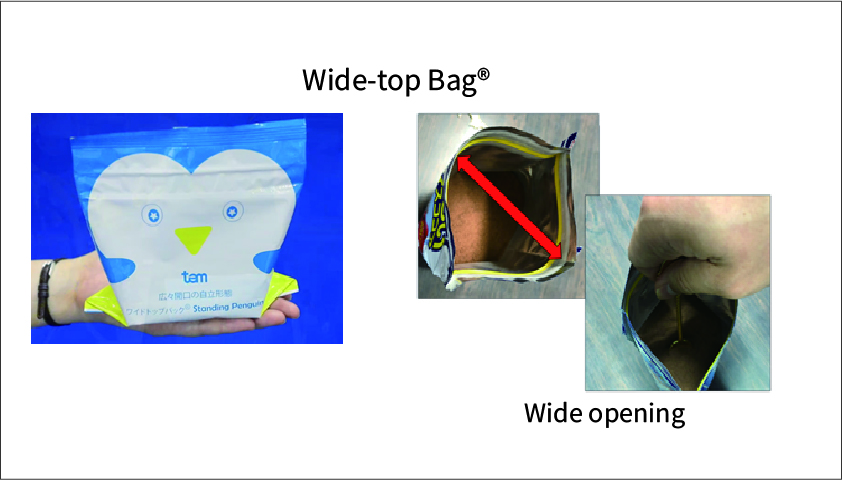

The zipper re-closing function increases the convenience when using. Due to the wide opening, it is easy to take the products out. The consumer can use just the amount they need when they want, and the zipper bag assures the good keeping.

■ Design

The self-standing gusset bag has better appearance when displayed in stores. The product can be appealed with print design to make use of the flat side of the package.

■ No need for replacing

The cereals, cocoa powder or seasoning powder are the products can’t be used all at once. The zipper bag that Tam manufactures by our VFFS machine can prevent moisture just the same as the pre-made zipper bag, so the product quality will be protected and maintained.

The “Wide-top Bag®” has both features of self-standing and convenience.

The square bottom style can show the package surface flat, so the design printing and the display appearance looks better. It is effective for the appeal in stores. This style is functionally superior that is able to pack larger amount with a small amount of the packaging material comparing to the standing pouch. The zipper re-closing function increases the convenience when using. Thanks to the wide opening of this unique style, it is very easy to t put your hand and spoon in the package to take the product out.

■ Necessary space and packaging capability

In the view of the actual operation, this model is space saving and have high performance comparing to the general packaging machine using pre-made bag.

The packaging output of TWN-ZH model is maximum 65 bags/min.

■ Specification

Bag Style: Pillow bag, Gusset bag, Block Bottom gusset, Wide-top Bag® (With or without zipper)

Bag Size Range: Bag Width 80 - 250mm, Bag Length 100 - 410mm

Packaging Speed: TWN-ZH Max. 65bags/min (bag width under 165mm , flat bag with zipper)

TWN-Z Max. 50bags/min (bag width under 165mm , flat bag with zipper)

Machine Dimensions: W 2470 x D 1850 x H 1600 mm

Machine Weight: Approx. 1300 kg

Things to be noted for introducing the machinery

■ Packaging material

In case the operation of the packaging output with 30rpm, one cycle of the VFFS machine takes 2 seconds. The sealing time is then calculated as approximate 0.6 seconds. The strong adhesive film of LLDPE is necessary since the materials with different thicknesses need to be heat-sealed. The zipper flange material is also LLDPE.

We explained the brief information of the zipper packaging in the above article, there would be further points to be checked and the determination of the proper specification is difficult. Please feel free to contact Tam for the correct choice of the zipper VFFS machine. We offer the most appropriate solution to meet the customer’s requirements and conditions by our long-years of experiences.

Tam Contact to: tam-overseas@tam-tokyo.co.jp